-40%

Navy Blue - Screen Printing Plastisol Ink - Low Temp Cure 270F - All Sizes

$ 10.13

- Description

- Size Guide

Description

Emulsion | Chemicals | Ink | Equipment | Inkjet FilmNavy Blue - Screen Printing Plastisol Ink - Low Temp Cure 270F - All Sizes

Key Characteristics:

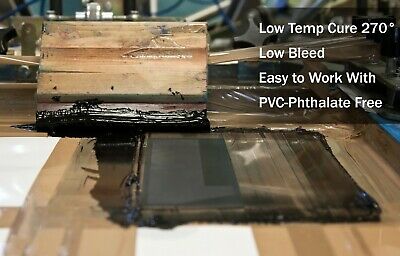

Low Temp Curing 270° F

Soft Hand Prints

Universal for Variety of Fabrics

Bleed Resistant for Poly Blends

Non Phthalate

The ultimate Non-Phthalate plastisol ink. Rapid Cure the best solution for printing on polyester and blends. Our Rapid Cure series cures at a much lower temperature. This ink will help avoid dye migration and scorching your garment. Test your substrate first to make sure the ink work properly.

Curing:

Cure at 132° C/270° F

Flash at 82-104° C/180-200°F

Flash and Curing Guidelines:

Generally it will take 5-10 washes to fully test the cure, but if the ink is seriously under-cured, the print will show deterioration after only 1-3 washings washes. Another way to test your print quickly is doing the “Stretch Test” stretch the print roughly 2/3 of the T-Shirt; if the print cracks and does not retract back it means you under-cured.

General Testing:

Before you do any large print, we recommend doing a stretch test and a wash test to ensure you cured and printed correctly before going into production. Increase cure time if testing fails. We recommend only using natural fibers best results will be seen on 100% cotton.

Clean Up:

On the press: Ecotex Plastisol Press Wash/Ink Degradant

In the sink: Ecotex Plastisol Screen Wash/Ink Degradant

✔️Pro Tips: Plastisol inks do not dye fabric like the traditional inks. Plastisol inks wraps around the fibers and makes a mechanical bond with the fabric. Store plastisol inks at room temperature. Prolonged exposure to temperatures above 90º F (32º C) can cause the ink to start to cure while it's still in the container.

We highly recommend printing with an under base white when printing on a dark garment

See our other items

Payment

Shipping

We accept payment by any of the following methods:

PayPal, Google Pay, Visa, Mastercard, American Express and Discover

We offer

FREE shipping

on all orders in the continental USA!

Your order will be dispatched same day after receiving payment (Monday-Friday) if order is made by 12:00 PM PST and you should expect to receive it two days after dispatch. If order is purchased together with multiple products your order may ship ground 3-5 days.

In the very unlikely event that your item is lost or damaged during post, then WE are responsible and will issue either a full refund or replacement.

About

Mission

Screen Print Direct promises high quality products at revolutionary prices. We have cut the middle man out of the equation and offer superior products straight from the manufacturer. We will continue to innovate and only produce the best products at the best prices.

Our Promise

We promise to always provide affordable high quality products. We also promise to offer the best customer service and best screen printing advice, your success is our success. Our customers are real hustlers and go-getters! We know the humble beginnings of a print shop and your ambitious attitude & drive inspires us daily!

Returns

If you are not 100% satisfied with your purchase, you can return the product and get a full refund or exchange the product for another one, be it similar or not.

You can return a product for up to 14 days from the date you purchased it.

Any product you return must be in the same condition you received it and in the original packaging. Please keep the receipt.

Shop By Department

Key Characteristics: ---Low Temp Curing 270° F ---Soft Hand Prints ---Universal for Variety of Fabrics ---Bleed Resistant for Poly Blends ---Non Phthalate The ultimate Non-Phthalate plastisol ink. Rapid Cure the best solution for printing on polyester and blends. Our Rapid Cure series cures at a much lower temperature. This ink will help avoid dye migration and scorching your garment. Test your substrate first to make sure the ink work properly. Curing: ---Cure at 132° C/270° F ---Flash at 82-104° C/180-200°F Flash and Curing Guidelines: Generally it will take 5-10 washes to fully test the cure, but if the ink is seriously under-cured, the print will show deterioration after only 1-3 washings washes. Another way to test your print quickly is doing the “Stretch Test” stretch the print roughly 2/3 of the T-Shirt; if the print cracks and does not retract back it means you under-cured. General Testing: Before you do any large print, we recommend doing a stretch test and a wash test to ensure you cured and printed correctly before going into production. Increase cure time if testing fails. We recommend only using natural fibers best results will be seen on 100% cotton. Clean Up: ---On the press: Ecotex Plastisol Press Wash/Ink Degradant ---In the sink: Ecotex Plastisol Screen Wash/Ink Degradant ✔️Pro Tips: Plastisol inks do not dye fabric like the traditional inks. Plastisol inks wraps around the fibers and makes a mechanical bond with the fabric. Store plastisol inks at room temperature. Prolonged exposure to temperatures above 90º F (32º C) can cause the ink to start to cure while it's still in the container. We highly recommend printing with an under base white when printing on a dark garment

Navy Blue - Screen Printing Plastisol Ink - Low Temp Cure 270F - All Sizes

Key Characteristics:

Low Temp Curing 270° F

Soft Hand Prints

Universal for Variety of Fabrics

Bleed Resistant for Poly Blends

Non Phthalate

The ultimate Non-Phthalate plastisol ink. Rapid Cure the best solution for printing on polyester and blends. Our Rapid Cure series cures at a much lower temperature. This ink will help avoid dye migration and scorching your garment. Test your substrate first to make sure the ink work properly.

Curing:

Cure at 132° C/270° F

Flash at 82-104° C/180-200°F

Flash and Curing Guidelines:

Generally it will take 5-10 washes to fully test the cure, but if the ink is seriously under-cured, the print will show deterioration after only 1-3 washings washes. Another way to test your print quickly is doing the “Stretch Test” stretch the print roughly 2/3 of the T-Shirt; if the print cracks and does not retract back it means you under-cured.

General Testing:

Before you do any large print, we recommend doing a stretch test and a wash test to ensure you cured and printed correctly before going into production. Increase cure time if testing fails. We recommend only using natural fibers best results will be seen on 100% cotton.

Clean Up:

On the press: Ecotex Plastisol Press Wash/Ink Degradant

In the sink: Ecotex Plastisol Screen Wash/Ink Degradant

✔️Pro Tips: Plastisol inks do not dye fabric like the traditional inks. Plastisol inks wraps around the fibers and makes a mechanical bond with the fabric. Store plastisol inks at room temperature. Prolonged exposure to temperatures above 90º F (32º C) can cause the ink to start to cure while it's still in the container.

We highly recommend printing with an under base white when printing on a dark garment

See our other items

Payment

We accept payment by any of the following methods:

PayPal, Google Pay, Visa, Mastercard, American Express and Discover

Shipping

We offer

FREE shipping

on all orders in the continental USA!

Your order will be dispatched same day after receiving payment (Monday-Friday) if order is made by 12:00 PM PST and you should expect to receive it two days after dispatch. If order is purchased together with multiple products your order may ship ground 3-5 days.

In the very unlikely event that your item is lost or damaged during post, then WE are responsible and will issue either a full refund or replacement.

About

Mission

Screen Print Direct promises high quality products at revolutionary prices. We have cut the middle man out of the equation and offer superior products straight from the manufacturer. We will continue to innovate and only produce the best products at the best prices.

Our Promise

We promise to always provide affordable high quality products. We also promise to offer the best customer service and best screen printing advice, your success is our success. Our customers are real hustlers and go-getters! We know the humble beginnings of a print shop and your ambitious attitude & drive inspires us daily!

Returns

If you are not 100% satisfied with your purchase, you can return the product and get a full refund or exchange the product for another one, be it similar or not.

You can return a product for up to 14 days from the date you purchased it.

Any product you return must be in the same condition you received it and in the original packaging. Please keep the receipt.

Shop By Department

Key Characteristics:

Low Temp Curing 270° F

Soft Hand Prints

Universal for Variety of Fabrics

Bleed Resistant for Poly Blends

Non Phthalate

The ultimate Non-Phthalate plastisol ink. Rapid Cure the best solution for printing on polyester and blends. Our Rapid Cure series cures at a much lower temperature. This ink will help avoid dye migration and scorching your garment. Test your substrate first to make sure the ink work properly.

Curing:

Cure at 132° C/270° F

Flash at 82-104° C/180-200°F

Flash and Curing Guidelines:

Generally it will take 5-10 washes to fully test the cure, but if the ink is seriously under-cured, the print will show deterioration after only 1-3 washings washes. Another way to test your print quickly is doing the “Stretch Test” stretch the print roughly 2/3 of the T-Shirt; if the print cracks and does not retract back it means you under-cured.

General Testing:

Before you do any large print, we recommend doing a stretch test and a wash test to ensure you cured and printed correctly before going into production. Increase cure time if testing fails. We recommend only using natural fibers best results will be seen on 100% cotton.

Clean Up:

On the press: Ecotex Plastisol Press Wash/Ink Degradant

In the sink: Ecotex Plastisol Screen Wash/Ink Degradant

✔️Pro Tips: Plastisol inks do not dye fabric like the traditional inks. Plastisol inks wraps around the fibers and makes a mechanical bond with the fabric. Store plastisol inks at room temperature. Prolonged exposure to temperatures above 90º F (32º C) can cause the ink to start to cure while it's still in the container.

We highly recommend printing with an under base white when printing on a dark garment